Gone are the days when glass is only used in windows. They look through glass to see out, but they don't think of it doing much else. Now, things have changed! We use glass in our homes; we see it everyday's important functionalities. I mean… our tables are all glass (as in plates loaded with nutrient for us to eat and drink on)! —,glass room doors, that glass stairs or even to leave space for light everywhere; That is why it are so important when to grind the sharp edges of said glass down flat and Safety. They may also be sharp, and if they are near the edge that can lead to accidents.

After glass is cut into individual pieces for shape, the edges are razor sharp. Like we need to be careful! The same can be extremely well done on the edge polisher machine. This fantastic machine has now sanded all the extra hard dark stuff up to a nice sharp & shinny edge of that glass. The cut off that ripping part is then replaced with the safer edges you can used on.

Curved-edge glass just plain looks better and way less budget than the flat stuff. A medium for the mirrors that hang on our walls, glass tables we eat from You also do not want rough or scrappy edges to destroy the luster of your pieceenses and decoration. No one should be willing to pay for anything that is filthy or potentially hazardous! We like the clean bent edges.

Providing rounded corners on glass not only serves to make it look good, but also adds substantial strength. When the glass is sharp and jagged along its edges, they tend to break or chip very easily. However run your fingertips through them after we've sanded those edges down, then you're cutting yourself on glass. So they are robust and long lasting. This is especially important if the glass needs to hang over, or it gets little use and might get punched.

So, it is very hard to polish glass like mirror long ago. I spent a lot of time and effort in making every edge perfect. During that process, your workers could have been severely injured. But progress in technology only also means much more efficient work — like edge polishing machines, producing an end result to near perfection. These machines are those to perform professionally in some manner, people produce more accurately glass objects.

Only possibility you have to get some thing like that decent with a piece of glass is when you got the right tools, say for making good looking flower vase or nice photo frame from your best pic. One of it is an edge polisher that can be used to ensure all your edges are safe and smooth. It is possible to produce attractive glass workable products, but you need the right equipment if they are going to look as good and safe for your guests at their next party. Think of all the pretty things we can syndicate with glass!

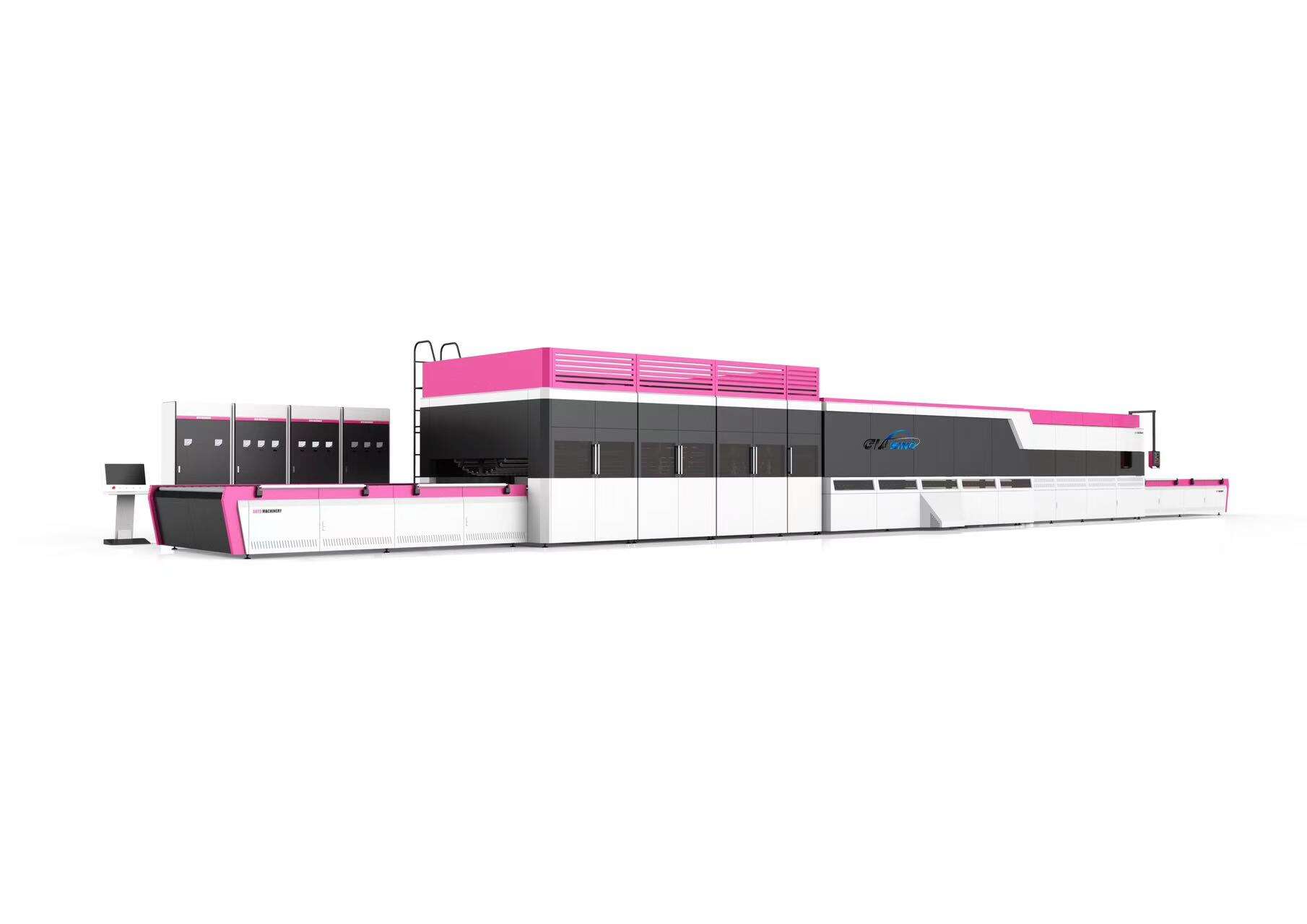

The factory is geared towards the technological advancement in the production process Innovation is the key to utilizing existing technologies and also develop new ones Develop production techniques that make the product more perfect Be competitive in the glass edge polisher

glass edge polisher cut down on the number of products that are defective, and to enhance customer satisfaction strict quality inspections are conducted. It is a solid quality control system in place to ensure continuous quality management. Improve inspection and testing methods

The factory glass edge polisher its production plan to market conditions, and it maintains its competitive edge. Produce flexible lines of production, and make use of information technology to meet market demand. Change production plans in time.

glass edge polisher factory enjoys the benefit of economies of scale due to the introduction of cutting-edge production equipment and technology Manual work is reduced Furthermore the speed of production with high-efficiency equipment tends to be faster which will quickly complete the manufacturing task and improve the production speed and efficiency