EOUIPMENT ADVANTAGE

◆ High sealing performance, High automation, Reduce labor cost, Save manpower cost, improve production efciency.

◆Fully intelligent and smart HMI in Touching Screen, with memory function and easy operation.

◆Best Sealing quality without air bubbles, smooth surface, avoid time for corner correction!

◆ For Model II: Using two sealant supply systems, two fast switch and one-button operation!

◆The width of machine is 1.4m, small foor area, save space.

◆The sections is one production line, it can prestore three pcs glass to improve the efhciency effectively.

◆The smallest insulating glass size can be processed is 300x300mm.

◆Equipped with anti blocking device in the mixer, easy to clean.

◆Servo control system adopts world famous brand (Japan YASKAWA ), the performance is stable, counting speed is fast, sealant output with high precision, surface with high smoothness.

◆Chain type transmission to make the glass being transferred smoothly with accurate positioning.

◆Special V type transmission belt to avoid the sealant sticking on the belt, ensure the glass edge clean, V type Block is changeable.

◆The spare parts are produced with high standardization and high precision, ensure the machine can be used with long-term stability.

◆Suitable for triple glazing.

◆Conveying wheel on backboard adopts embedded wheel, to make sure the glass be transported smoothly.

◆Equipped with high speed positioning fimction, glass can be located accurately when transport fast.

◆Touch screen adopt ethernet communication, sensitive operation, suitable for popular operation.

◆Keep machine service and upgraded timely with our own R&D departments.

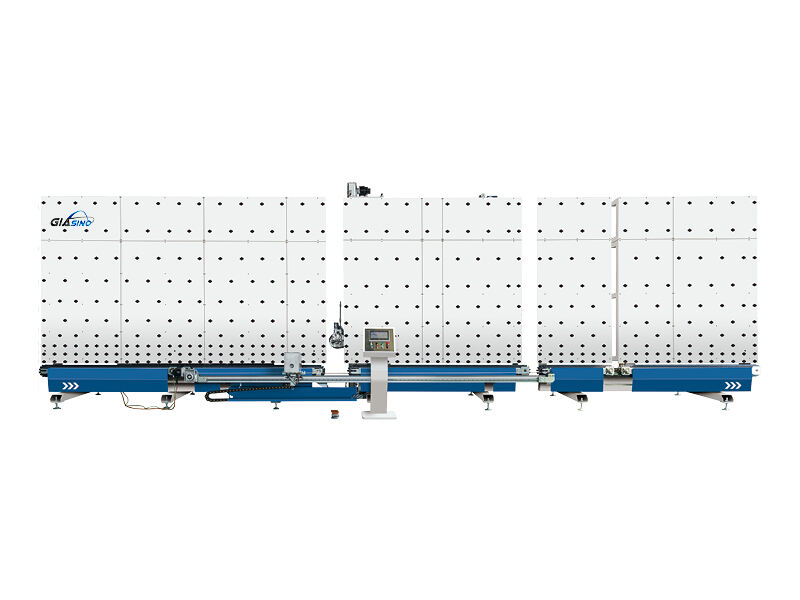

TECHNICAL PARAMETER

| Model | Voltagepower | Airpressure(MPa) | Squeezepressure(MPa) | Max.Glass size(mm) | Min.Glass size(mm) | Glassthickness(mm) | Workingspeed(m/min) | Overalldimension(mm) |

| ZNJ2025-I/II | 380V 7kw | 0.6-0.8 | 32 | 2000x2500 | 300x300 | 12-56 | 5-40 | 8030x1400x2950 |

| ZNJ2540-I/II | 380V 7kw | 0.6-0.8 | 32 | 2500x4000 | 300x300 | 12-56 | 5-40 | 8630x1400x3500 |

TECHNICAL DESCRIPTION

-The robot applies single component hot melt sealant.

-Finished sealed IG units can be stored on the third conveyor to increase efficiency

-Economical and practical for all glass fabricators

-All edges and corners are fully sealed with no voids, leaving a smooth surface without manual corner treatment

-Servo control system using world renown brands (YASKAWA)

-Belt conveyor smoothly transfers and positions the glass by servo motor

-Unique V belt delivery system reduces sealant to belt contact which results in cleaner glass, also has replaceable inserts for easy maintenance and cleanup

-High quality materials used throughout to extend the longevity of the equipment

-Integrated heating system and thermal sensors controlled by an electronic controller monitor to make sure the required processing temperature for the hot melt materials.

-HMI is user friendly and designed for convenient fabrication

Feature:

1. Controlled by Japan Yaskawa servo control system.

2. Use dual system A rubber plunger pump and B rubber plunger pump and hydraulic proportional pump. One key switch system function. Customers can be in different

Quickly switch in the sealant-like. Convenient and fast, improve work efficiency.

3. With touch screen interface, manual operation and fault diagnosis can be realized.

4. Two sets of mixer cleaning systems, easy to maintain

5. Can be used for rectangular and square hollow glass

6. A special sealant depth detection device can automatically control the amount of sealant applied.

7. The sealant supply and proportioning system of the hydraulic system can provide stable sealant output and precise ratio of A and B components.

8. Automatic sealant discharge function to avoid pipeline blockage caused by human factors.

Technical parameter:

Maximum glass size |

2000mmx2500mm |

Minimum glass size |

160mmx310mm |

IG units thickness |

12-56mm |

Coating speed |

Adjustable 5-40m/min |

Coating depth |

≤15mm |

Air supply |

2m3/min |

Power |

30KW |

Spare parts brand:

Our friendly team would love to hear from you!