Edge banding machine (features): It is a special equipment used in can beading, which will help you edging( adding strips of material to the edges). It is a trick to hide the raw stitches on edges, so they look neat and professional. An edge banding machine is perfect for when you need your projects to look their best. And the amazing fact is, with this machine, you can do it rather quickly as well. You will avoid having to put the strap of fabric by hand, which depending on how tired and hard it is may take a long time.

How does it work: you get your woodworking project and start putting it inside the machine. Next, the machine places that strip of material onto your project's edge. That strip is heated, so it adheres to your project much like hot glue does. It guarantees a strip that is melted together and adhered to stick by refraining from having it lifted up off the nail easily. This will help you not afraid of spoilage later on.

If you are doing a woodworking project, the object of making it look nice is important. It should not look neat and tidy but it does. You for sure do not want those scraggly ends sticking out looking a hot mess, only GROWN WOMEN make that cute. an edge banding machine comes in handy here. You can use a smooth edge blading each time.

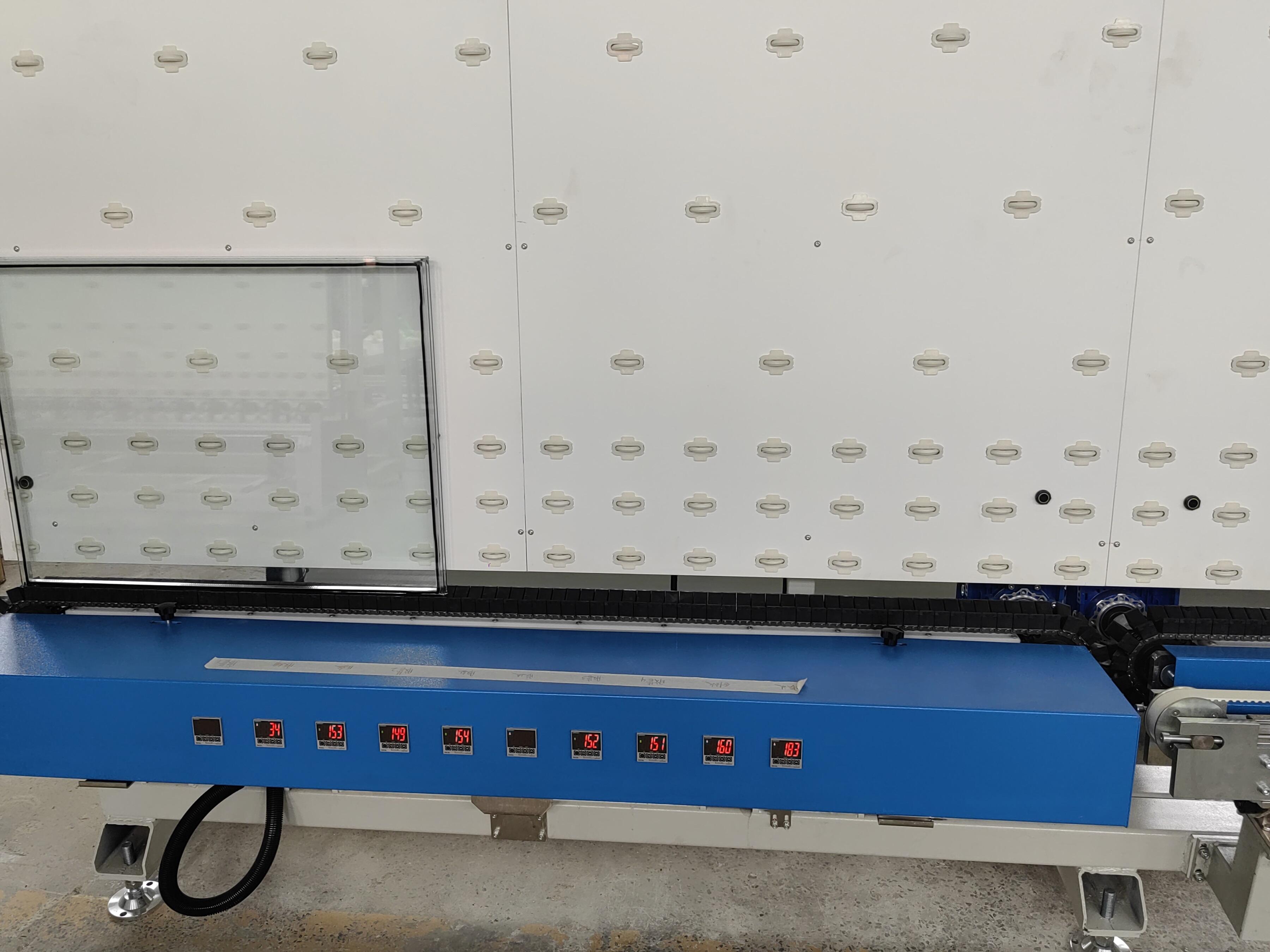

The machine utilizes smart technology to ensure that the strip of material is evenly applied on the edges. This means that your edges when you are done will look very neat and professional. You will not need to struggle with rough spots or an end result of your effort being more than less ruined. Instead, you can have peace of mind that your project will turn out exactly the way it should.

If you follow woodworking at all, you know that it can take quite awhile to apply a strip of material edging by hand. It is always a test of patience and skill, and still it never looks quite right even when you give your best. An edge banding machine to the rescue. It also speeds up your workflow time and saves precious working hours.

This machine eliminates having to try and get the edges perfect all day. All you do is stick your project in the machine and it does everything else. That is time that you can spend on other aspects of your project or even complete more projects in a shorter timeframe. This is an excellent benefit for any woodworker looking to complete projects efficiently.

It is useful in crunching almost every kind of narrow material, whether it be a thin wood or thick metal. There is no need for you to worry whether the machine can handle that, because it is capable of being used on different thicknesses and materials. If you work on a lot of different types of projects, which is common for both hobbyists and professionals alike this flexibility is probably going to be great.

To decrease the edge banding machine of products that are defective, and to improve customer satisfaction, strict quality inspections are conducted. A solid quality management system to attain continuous quality management. Improvements in inspection and testing techniques

The factory can benefit from economies of scale Thanks to the introduction of automated production and modern equipment the manual labor requirements are reduced edge banding machine can also create at a higher rate and increase production efficiency and speed

In accordance with the edge banding machine condition, the factory adjusts the production plan in time to keep up with changing market demand and maintain an edge in competition. Implement flexible production lines, and make use of information technology to efficiently meet consumer demand and alter production plans quickly.

edge banding machine factory focuses on technological innovation in the production process Develop new technologies and innovate using technology that is already in use Improve the production process Keep your product competitive on the market