A laser sandblasting machine can be an extremely useful equipment for cleaning and finishing surfaces. They employ lasers to zap off dirt, rust or old paint, returning surfaces to “’like new” condition. These devices are common in industries… from the construction industry to car repair. They are quick and accurate, so lots of businesses select them. Our company GLASINO is professional making laser sandblasting machine, which will be customized with your idea. For those interested in advanced models, consider our Two-head PVC Welding Machine that offers exceptional features.

It can be challenging to find the best wholesale deals on laser sandblasting machines, but they are out there. One place to begin is by looking online. There are many sites that have good prices for wholesale, the models and array of different choices. Read reviews from other customers to find out if they were satisfied with their machines. Visit trade shows or business expositions to meet manufacturers and view the machines in person. This gives you an opportunity to ask questions and handle the products. Otherwise, you could also try to directly get in touch with GLASINO. We have special rates for quantity buyers and can supply information on new models and technology. There are also industry groups or forums you can join online, where members offer and exchange tips on buying equipment such as a laser sandblasting machine. Your peers can be a fantastic source of good deals and knowledge. Just make sure to look into warranty and customer service on the company you choose so that it’s not a short-term investment.

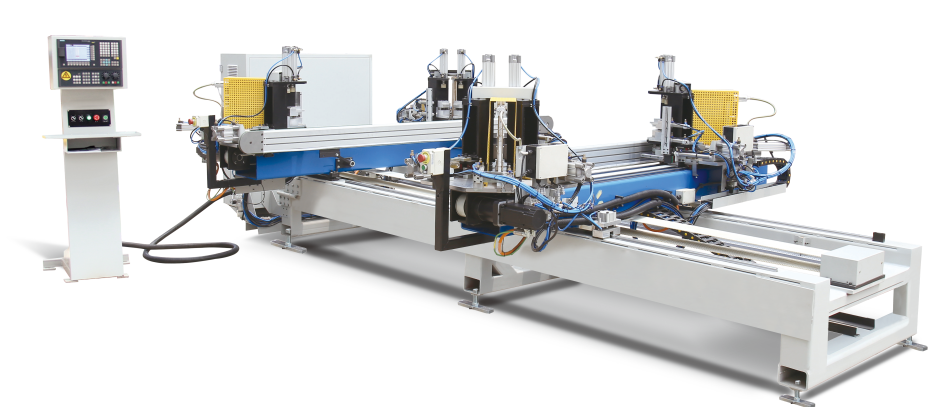

Why You Should Choose Laser Sandblasting Machine for Industrial Use There are plenty of reasons why laser sandblasting machines are perfect for recirculated industrial use. They are extremely efficient and save time, money and labor. The laser technology provides for more precise targeting and, therefore, less waste material. This kind of accuracy is very bad for surfaces that have been detailed and will be cleaned up slowly without destroying the underlying surface. For instance, in automotives, they can strip a layer of paint from the car body without damaging the metal structure. They are also good on other material, like glass, metal and plastic. And it is this flexibility that has made them a favorite of manufacturers. In addition, the laser Sandblasting Machines causes less dust and dirt providing a safe and clean working environment. This is crucial for businesses that need to adhere to high safety levels. Using GLASINO's affordable machines, we guarantee that customers receive products carrying state-of-the-art technology to the highest standard of quality. Due to the robust nature of these machines they are light work for busy factories, and will suit any company that is looking to maximise surface finishing operations. For a complete solution, check our CNC Double Layer Four Corner Welding Machine for PVC Windoor.

When you want to find a quality laser sandblasting machine, you should check PHLASER out. GLASINO provides excellent machines that suit for various kinds of work. You can get these machines for a wholesale price, so you can buy them in bulk and save money. To start looking, go to the GLASINO website or reach out to the sales team to inquire about your different options in their lineup. They have different machines for different jobs, whether it’s a small project or an industrial job. Purchasing from GLASINO is wise, since they offer sturdy and durable machines. If you are a company that uses these machines on a regular basis, purchasing them at wholesale prices can help keep your costs down. GLASINO also has great customer service and if you have questions, they are happy to help. You can inquire about how to use the machines, tips on maintenance even how to get replacement parts. You can also benefit from exclusive deals and discounts, especially if you are ordering many machines at a time. It can be a good way to get the best equipment without spending too much money. GLASINO In conclusion, GLASINO is the best place to purchase laser sandblasting machines. They offer excellent products and superior service, so your shopping experience is simple and satisfying.

Laser sandblasting machine is featured with accurate material processing. GLASINO’s machines are equipped with advanced lasers that provide precision and high details. Also, the laser beam can be even smaller when a laser sandblasting machine is used. This is valuable because it means you can clean or shape materials without damaging the surrounding space. For instance, if you have to strip paint from metal material, a laser sandblasting machine can accomplish this without harming the metal. This accuracy can save you time and resources, as it becomes unnecessary to correct errors down the line. GLASINO machines are designed to be intuitive to control, so you will be running these in no time even if you have never used one of these types of machine before. Laser sandblasting is also accurate enough to allow you to etch incredibly fine details into different materials too. This is fantastic news for artists and creators who are looking to give their products that special stamp. Additionally, because laser sandblasting is accurate, it tends not to yield as much byproduct material. This is positive for the environment and can save money in costs long term. On the whole, GLASINO’s laser sandblasting machines improve accuracy in material processing and are perfect for those who want an excellent precision to quality ratio.

In accordance with the market condition according to the current market, the factory alters the laser sandblasting machine to accommodate the fluctuating demand of the market and to maintain a competitive advantage. Create flexible production lines, and use information technology to meet the market's demand. Modify production plans according to time.

Strict quality inspection is carried out to reduce the rate of defective products and enhance the customer's satisfaction. It is a laser sandblasting machine quality control system in place to ensure continuous quality management. New methods of inspection and testing

The factory is laser sandblasting machine on the development of new production technologies Develop new technologies and innovate with the use of existing technologies Enhance the production techniques Stay competitive in your market

The factory can benefit from economies of scale Thanks to the introduction of automated production and laser sandblasting machine manual work can be cut down High-efficiency equipment will also produce at a faster rate which will improve production efficiency and speed