So you ever look at a window and say that looks like that window has two pieces of glass. It doesn’t splinter into countless sharp pieces when you attempt to break it like normal glass. That special type of glass is referred to as safety glass! Safety glass sticks two pieces of glass with a special plastic called PVB. Want to know more on the making of safety glass? That's where the GLASINO laminated glass cutting machine comes in, and it is essential in this process!

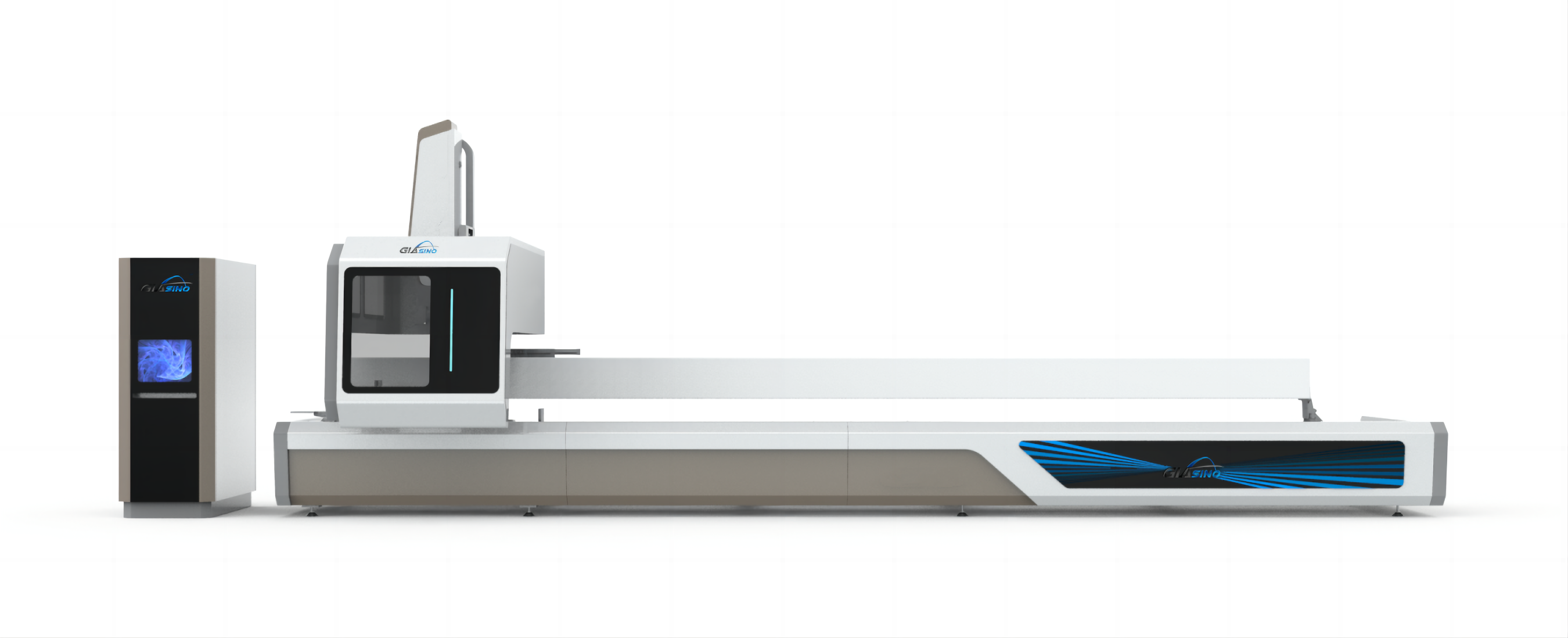

These machines are used for cutting laminated glass which are very important for making safety glass. You can find safety glass in many places, including car windshields, doors and windows, to skylights that let light into buildings. Suppose we didn’t have safety glass! If someone broke a window by mistake, we could get badly hurt. This is why safety glass needs to be present in our daily lives. Laminated glass cutting machines help to ensure that the safety glass is manufactured correctly. They trim the two pieces of glass to size and ensure they are perfectly aligned with the PVB plastic. One of the best companies, which creates this type of glasscutting machine, is, of course, GLASINO.

In such cases, laminated glasscutting machines facilitate the cutting process of glass. Centuries ago, modern glass cutters had not been invented and people had to scratch a line on the glass, e.g. the line they'd like to cut. Then they would manually hand-cut along that line using a special knife. It was very Very slow and not very accurate. But now, things have changed with the use of laminated glasscutting machines! The machine is computerized so it knows exactly where to cut the glass. Which means it makes a perfect cut through the glass every time, speeding up and improving the entire procedure!

There are several benefits of using machines for cutting laminated glass especially for large jobs. This helps the job be more efficient, for example when a lot of glass needs to be cut for a bigger building; a laminated glass cutting machine can help get the job done much quicker and much more precise. This is really important, because in big projects you want to do everything right. Workers can save time and money by using these machines. Having the machine cut the glass rather than people doing it by hand is much more efficient. That is where GLASINO laminated glasscutting machines come in to take care of these big jobs!

Precision and high performance are the key features of laminated glasscutting machines. That’s because they’re guided by a computer that directs the machine exactly where to cut the glass. ىAlso, the machine can slit the actual glass wayfaster than a human can. Oh, and it also scores the glass perfectly every single time! This means a lot less waste, which is good for the environment. These machines allow us to make more safety glass using less material, which also helps minimise waste. GLASINO lamination glasscutting machines proveprecision & efficiency in glass cut & thus are the best choice for glass cutting!

A huge number of laminated glass cutting machines can be found on the market. As an example, there are some smaller machines, designed for glass shop usage, which are able to handle smaller jobs. Others are quite large, and are designed for industrial jobs, in which a big volume of glass has to be cut quickly. Some machines rely on laser cutting the glass, while others use a diamond blade, which is extremely sharp. A few machines will even be able to cut curved glass while some are only designed for flat glass. To fulfil the needs of the customers, GLASINO provides variety of laminated glass cutting machine so that everyone can find a tool for their tasks.

The factory can adapt its production schedule to the market and keeps a laminated glasscutting machine. Develop flexible production lines and utilize information technology to satisfy the demands of the market. Make adjustments to production plans in timing.

The factory can benefit from economies of scale Thanks to the introduction of automated production and modern equipment the manual labor requirements are reduced laminated glasscutting machine can also create at a higher rate and increase production efficiency and speed

To decrease the laminated glasscutting machine of products that are defective, and to improve customer satisfaction, strict quality inspections are conducted. A solid quality management system to attain continuous quality management. Improvements in inspection and testing techniques

The focus of the factory is on technological advancement in the production process Develop new ways to use laminated glasscutting machine technologies and develop new ones Enhance the production techniques Stay competitive in the market