Radiation spots filter among the common problems of many GLASINO Chinese flat glass factories. These spots can cause the glass to look unattractive and reduce its quality. They happen because of microscopic defect parts that can occur in the glass cutting machine, like nickel sulfide and iron oxide. These impurities can lead to chemical reactions when the glass is melted to an intense heat in the furnace. This causes little bubbles to form on the surface of the glass. Over time, these bubbles become “radiation points” that are visible to our eyes, which gives an appearance of cloudiness or marks on the glass.

All in all, Another important impact is that, new technologies and methods are being developed by research organizations to eliminate this issue. However they might not be able to get rid of them entirely, and one way to cut down on these spots is to use precious, low impurity raw materials. That translates to cleaner and better raw materials for the glass itself. These high quality materials allow the glass to be clearer and look better overall when it is finished.

Particularly in flat glass, it is crucial to monitor the GLASINO cutting machine glass quality closely to help minimize the number of radiation spots. Factories should ensure that when glasses are heated, the furnace is working under the right temperature. Another very useful tip is to reduce the oxygen level in the furnace you will use for heating. This is accomplished by injecting some hydrogen or nitrogen gas into the furnace. This will help to keep satellite hotspots from blistering on the surface of the glass by creating better conditions inside the furnace.

Flat glass quality is highly influenced by radiation spots. When these spots occur, they make the glass more cloudy and less see-through. This is not something customers like because they want glass to be bright and transparent.» Additionally, the radiation spots might weaken the glass, so it can crack or break more easily. Header text: The safety of glass cutting table is a concern that we take seriously. Because radiation spots have become a real concern for manufacturers.

There are multiple methods to overcome the challenge of radiation spots in the flat glass production process. This is a problem that factories can solve by leveraging better technology and enhancing their processes. In some cases, nasty stuff contaminating raw glass cutting machine cnc can be caught before being heat-treated by sensitive filtering systems, for instance. This helps manufacturers avoid the development of radiation points during heating. By enforcing quality control measures of their own and checking the tempering process consistently, factories can also ensure that their glass products meet high quality specifications.

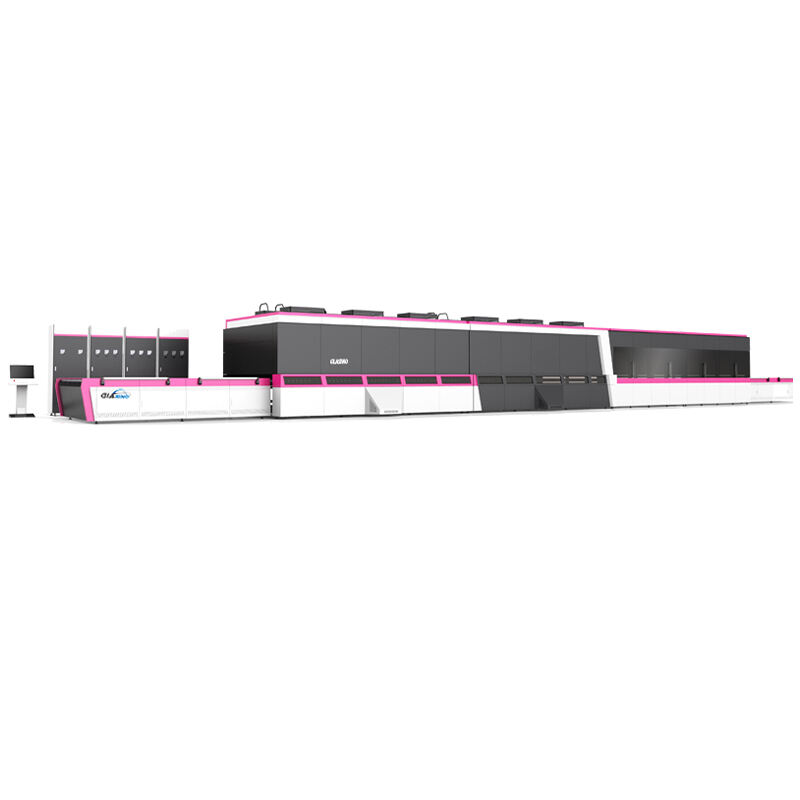

At GLASINO, we ever made to serve with the topmost flat glass products to our clients justified their purpose following their requirements and expectations. However, we recognize the difficulties associated with radiation spots that may lead to loss in flat glass tempering furnace production, so we have been committed to research, identify the emergence of new methods and technologies. Our top-of-the-line production facilities paired with our knowledgeable team of professionals ensure that our flat laser glass cutting machine products are the right solution for your needs — always reliable, safe, and of high quality.

The factory is focused on technological innovation in the production process Develop new ways to use existing technologies and also develop new ones Improve the production process Stay China radiation flat glass tempering furnace spots in the market

According to the market situation, the factory adjusts the production plan according to the market conditions in order to accommodate the China radiation flat glass tempering furnace spots market demands and keep its competitive edge. Develop flexible production lines and make use of information technology to meet the demand of the market. Change production plans in timing.

Strict quality inspection is conducted to China radiation flat glass tempering furnace spots the number of products that are defective and increase customer satisfaction. The company has a well-established quality management system to attain continuous quality control. Improve inspection and testing methods

Our factory is China radiation flat glass tempering furnace spots to take advantage of economies of scale through the introduction of advanced production equipment and technology manual work is reduced Moreover the speed of production for high-efficiency equipment tends to be faster which can quickly complete the production task and boost the speed and efficiency