The Making of Aluminum Windows and Doors in the Past, it was Quite a Work of Recovery, but with CNC Machines, Everything has become Much Simpler and Quicker. GLASINO — a factory for the production of high-quality aluminum windows and doors using CNC technologies. In this article, you will get to know how GLASINO in these machines and how these machines help GLASINO manufacture good products for customers, while improving the manufacturing process.

GLASINO aluminum profile window door cnc processing constantly strives for improvements and innovative solutions in the design and production of aluminum windows and doors. They ensured that the machines they use not only make the products strong but also the products are of high quality. A small but dedicated team of craftsmen manages it all, all the way from product design to actual CNC machining. This team puts in a lot of effort ensuring that everything is completed perfectly, and that the end result is precisely as customers envisioned.

GLASINO is dedicated to producing amazing products and re-invests into the latest machines and technology. This allows them to make sure they have an amazing status in this market. Every stage is attended to by their experts, from selecting suitable materials to delivering the end products on time and in the right condition. The careful monitoring is what distinguishes GLASINO as a leader in quality manufacturing.

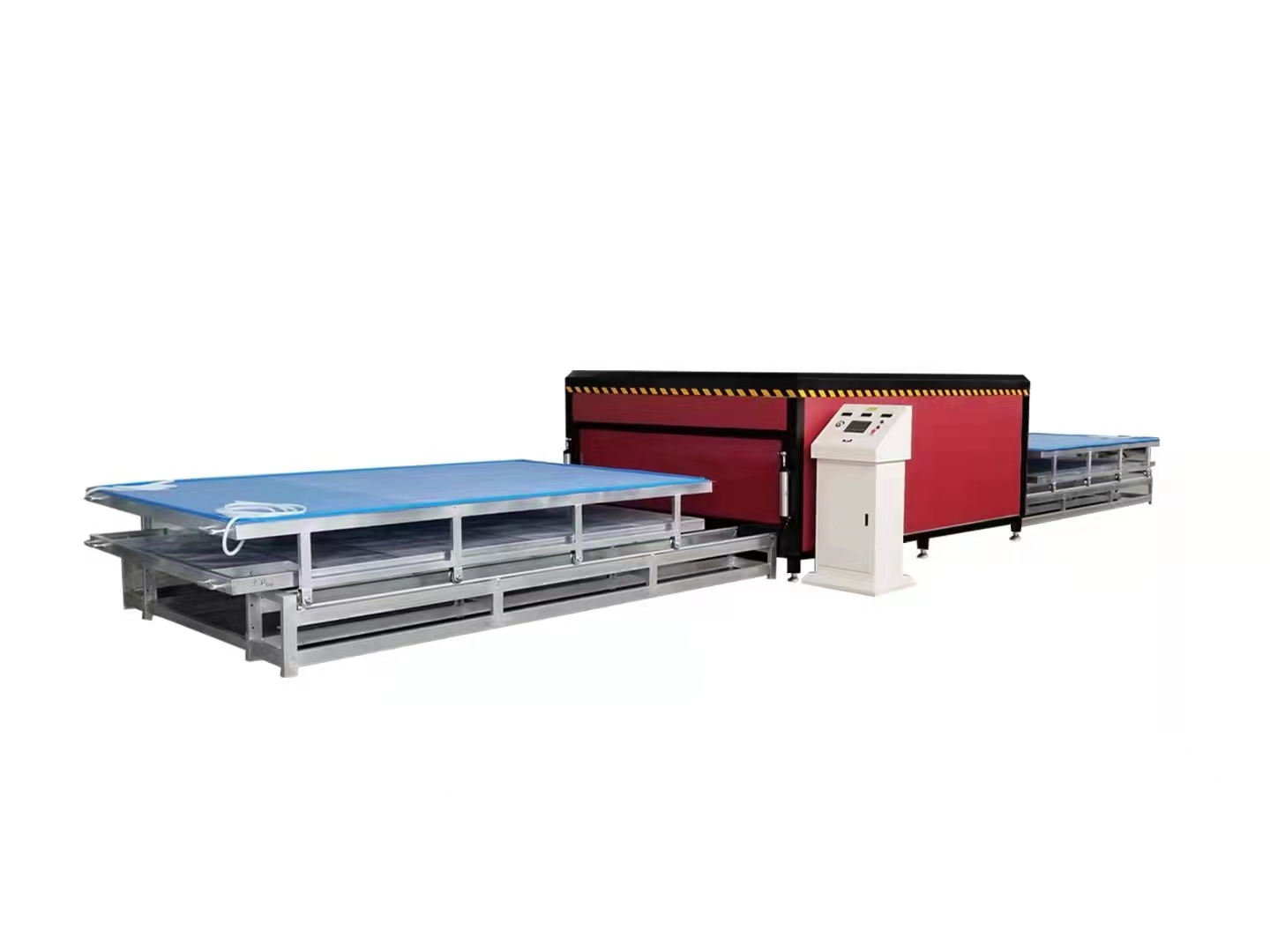

CNC (Computer Numerical Control) machines are one of the biggest advantages of modern production methods and GLASINO has become more innovative and faster and better in the production window and door solutions of aluminum since using CNC machines. Only when CNC technology was used, did the manufacturing process become faster, and the products' quality became consistent. But since they switched to a CNC (computer numerical control) machine, GLASINO aluminum profile window door cnc processing company can produce high-grade products with significantly fewer errors.

CNC machines also expedite the manufacturing process. CNC machines the aid them have made them do in a matter of hours instead of days for instance, difficult designs that would take forever to complete designing by hand prove to be very fast to make. This 60% time reduction in production will enable GLASINO advanced automatic aluminium profile cutting machine to produce more products in less time than ever, thus enhancing the overall productivity of the company and meeting consumers' demands.

CNC Machines and Aluminum Window and Door Production

The advent of CNC machines has revolutionized the production of aluminum windows and doors. Due to this technology, GLASINO has been able to come up with new and innovative designs that cannot be achieved with any other manufacturing process. That is to say, they can also serve other companies that have a need for custom-built sturdy and lovely windows and doors require custom-built sturdy and elegant windows and doors.

Today, GLASINO has just completed its superior team of experienced working staff that leads the whole manufacturing process. This abundance of experience and knowledge allows GLASINO to constantly develop new, enhanced solutions meeting the increasingly changing needs of this industry. Such commitment to quality makes GLASINO a worthy partner for anyone seeking the best aluminum windows and doors.

The factory is able to adapt its production schedule to market conditions, and it maintains an edge in the market. Create flexible production lines, and use information technology to meet the market's demand. Change production plans in the Aluminum profile window door cnc processing factories of time.

The manufacturing facility benefits from the benefits of economies of scale Thanks to the Aluminum profile window door cnc processing factories of machines that automate production and other advanced equipment manual work can be cut down High-efficiency equipment is also able to create faster which will improve the efficiency of production and speed

The factory is geared towards the technological advancement in the production process Innovation is the key to utilizing existing technologies and also develop new ones Develop production techniques that make the product more perfect Be competitive in the Aluminum profile window door cnc processing factories

To reduce the number of defective products, as well as to increase customer satisfaction, strict quality checks are carried out. There is a sound quality management system that allows for Aluminum profile window door cnc processing factories quality control. Improve testing and inspection methods