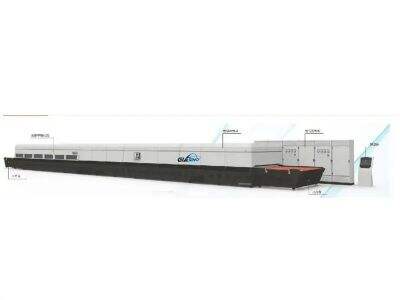

Glasino provides the complete sets of glass tempering furnaces

To crystallize high quality of tempered Glass products as requirements. However, just as with any other equipment, glass tempering furnaces can develop issues that may slow down its functioning In this post we will list out common problems that you can find with glass tempering furnaces and show you how to troubleshoot them efficiently Therefore keep up reading if somehow the set fails down there The first obvious problem is not heating of either top heater or.

Glass Tempering Furnace Not Working – Troubleshooting and Solutions

Non-uniform Heating: With glass tempering ovens, one common problem is non-uniform heating that can cause unevenness in the tempering process and sometimes even cause the glass to be shattered. The solution for this: Inspect your heating elements, they may be damaged or worn out or not working properly. You should also clean the heater on a regular basis to ensure there is no residue making it difficult for heat to circulate.

Cooling System Breakdown: The cooling system breakdown is another essential factor of tempering failure when the tempered glass will not cool in an adequate timely manner. For you to solve the problem, check if your cooling fans and water lines are not blocked and that it works fine. Ensuring that cooling system is well adjusted so it can obtain the correct rate of cooling required for tempering glass.

Sensor Calibration Faults: Faulty calibration of the sensor may also lead to incorrect tempering and defects on the glass. To correct for this problem, follow the manufacturer’s instructions to re-calibrate the sensors, and ensure that they are correctly placed in order to sense the glass temperature. Perform routine inspections of the sensors and repair or replace as needed.

Optimizing Glass Tempering Furnace Performance

Consistent Maintenance: Keep your glass tempering furnace in top working order by following regular maintenance tasks that include cleaning, greasing moving parts and checking the components for wear and tear. Maintaining your furnace will protect you from breakdowns and guarantee reliable operation.

Settings optimization: Optimization of tempering parameters including heating and cooling rate can assist in optimizing the performance of your glass tempering furnace. You can continue with trials and the various parameters to find out what is best for a quality glass output.

Training and education: Training your operators to know how to use the glass tempering furnace efficiently will let you get better benefits of this valuable equipment. Train your team on proper use, safety guidelines and troubleshooting to enable them to effectively use the furnace and resolve any issues.

Avoid Common Pitfalls in Glass Tempering Ovens

Frequent Checking: A regular check on your glass tempering furnace can show an early warning sign of an impending problem before it becomes a breakdown. Check all utilitarian parts (heating elements, cooling system and sensors) for wear, cracks or malfunctions and repair as soon as possible.

Schedule Maintenance: Develop a maintenance schedule for your glass tempering furnace and stick to it religiously. Plan regular jobs like cleaning, lubricating and parts checking to keep your tempered glass furnace in the best possible working condition and always ensure that it runs at its most optimal level of efficiency.

Quality Control: Apply a full quality control system on the temper glass, and make sure it is with no defect. With strict quality standards upheld, you will be able to avoid typical problems in glass tempering ovens, and you can make sure that your products are of the requested specifications.

You Better Be Keeping Your Glass Tempering Furnaces in Best Shape

Temperature Tracking: Inspect Control temperature inside the glass toughening furnace on a periodic basis, is maintained as per required for toughening. Measure the glass temperatures by using thermocouples or infrared sensors and adjust to optimize performance.

Calibration Checks Standard calibration checks of sensors and heating elements (heaters) within the glass temper lines are conducted to maintain constant temperature control. Errors in calibration result in incorrect tempering and will therefore affect the quality of the tempered glass products, hence it is very important to keep proper calibration.

The operator training: complete from a to Z the operator training on how treat and maintain the glass oven tempering furnace for a higher efficiency. Give your team training, safety information and troubleshooting guidance to ensure that you get the most out of your furnace.

Professional Solutions of Glass Tempering Furnace Troubles

Technical Support: If there are serious problems or permanent failures in your glass tempering machine, please contact the manufacturer for technical support or professional technician. Mature technicians can diagnosis the issue, and know exactly what you need to fix your furnace, so it's working well.

Upgrades and Retrofitting: Think about upgrading or retrofitting your glass tempering furnace with new technology or parts to enhance performance and efficiency. Other updates, like an efficient blower or a new burner with flame adjustment, will make the glass bending furnace more efficient and extend its life.

Maintenance Contracts: Make a contract with the manufacturer or authorized service provider to get your glass tempering furnace checked, maintained, and repaired at regular intervals. Regular ongoing professional maintenance can help to avoid potential problems, elongate the life of the furnace and also prevent it from having reduced performance in the long term.

by troubleshooting on issues, tuning the function to get max out of it, preventing from problems and well performing and find a fast solution from the expert guys you can! overcome problem with your GLASINO glass tempering furnace to keeping steady quality grade's production. Routine preventive maintenance, operator training and quality control are integral components of good furnace operation, but technical assistance, upgrades and service contracts offer additional solutions for lasting performance and durability. With proper preventive action and expert assistance, you can deal with any problems that arise, keep your glass tempering furnace well maintained, and ensure it continues performing to meet your production demands.

Table of Contents

- Glasino provides the complete sets of glass tempering furnaces

- Glass Tempering Furnace Not Working – Troubleshooting and Solutions

- Optimizing Glass Tempering Furnace Performance

- Avoid Common Pitfalls in Glass Tempering Ovens

- You Better Be Keeping Your Glass Tempering Furnaces in Best Shape

- Professional Solutions of Glass Tempering Furnace Troubles

EN

EN

AR

AR

FR

FR

DE

DE

PT

PT

RU

RU

ES

ES