In building homes and offices nowadays double glazing glass is the most important factor. This glass is used in buildings to warm the inside of buildings and provide protection from the elements, such as rain, snow and wind. It creates strong, sturdy looking buildings that many tend to find attractive. After all, creating double glazing automatic glass cutter is not an easy task. It is a long process and involves not very crude work. This process can be aided by machines having CE certification, making it a better and faster process

The CE marking explains to businesses what they must do in order for their glass to become energy smart, soundproof, and weather resistant. For instance, the glass needs to retain the heat inside in winter and prevent noise from the outside. Companies also have to look for any potential risks to ensure that the glass remains safe for all who use it. Such certification enables glass cutting line makers to sell their goods in the Europe and in some other regions around the globe if it follows the appropriate safety regulations. It also encourages businesses to upgrade their glass offerings to ensure they are safe for all consumers.

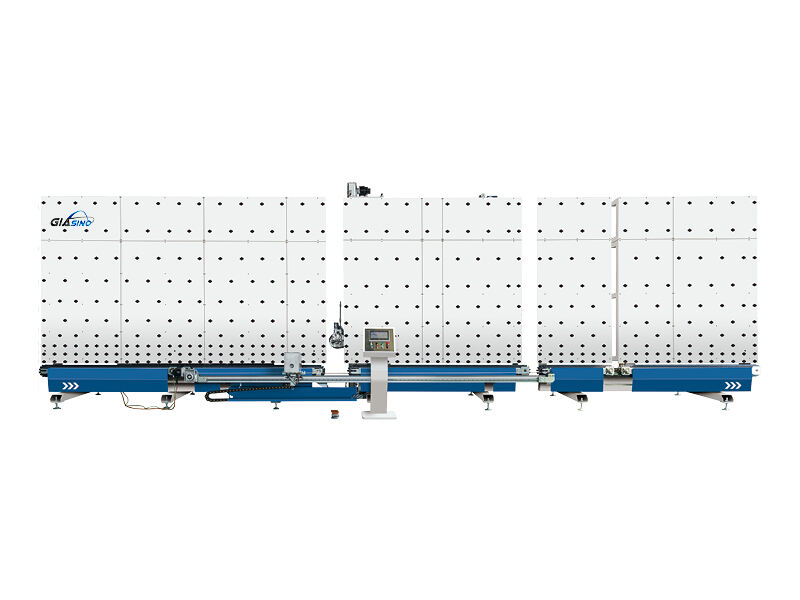

CE certified machines are tested before selling due to guarantee proper work of the program evolving on this machine. Those certified machines are used for faster and better quality cnc glass cutting making. Today, this means companies can save money while increasing the amount of glass they produce in less time. For this reason, when organizations purchase certified machines, they can be confident in knowing their machines will work properly and allow them to make quality glass products that their customers can rely on.

CE is one of the key requirements that push glass manufacturers towards better machines that keep their production process a few steps ahead. CE certification is basically an inspection to make sure the machine complies with the standards for being included in the European market. This also allows companies to comply with international safety standards, thereby reducing safety-related hassles. Companies are able to have a smooth production process and good reliable products with CE certified machines.

The double glazing glass area is very dependent on the importance of CE certification. It indicates that safeguards are made before the glass can be offered to customers. In such a case, the lack of this certification would leave the products unsafe, and the potential hazards to be caused. CE certification is needed so as to guarantee the safety of the products, enhance the trust in the products, and contribute to an efficient manufacturing process. Certification makes it easy for companies to market their glass in Europe, allowing them to expand and establish a reputation in the industry.

In order to Double glazing glass production line ce certification the number of defective products and to increase satisfaction of customers, strict quality checks are performed. There is a sound quality management system to attain continuous quality control. New methods of inspection and testing

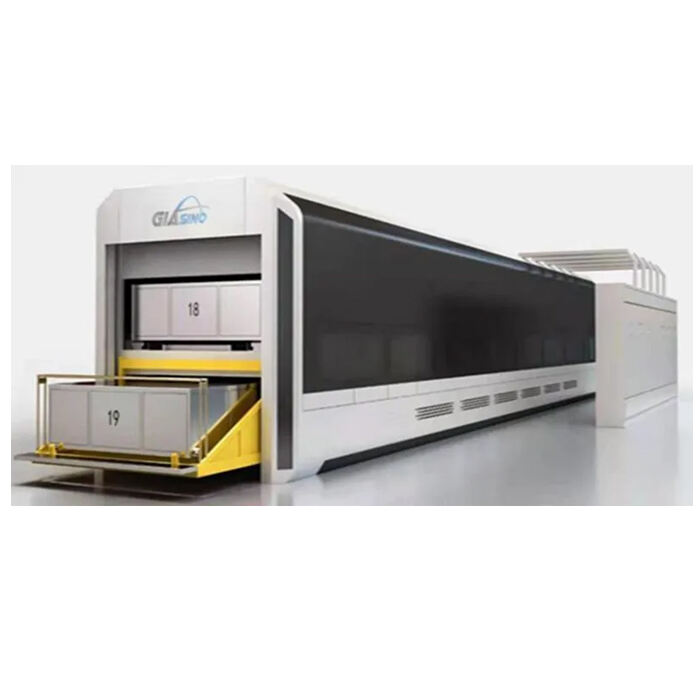

The manufacturing facility benefits from the benefits of economies of scale Thanks to the Double glazing glass production line ce certification of machines that automate production and other advanced equipment manual work can be cut down High-efficiency equipment is also able to create faster which will improve the efficiency of production and speed

The factory can adapt its production schedule to the market and keeps a Double glazing glass production line ce certification. Develop flexible production lines and utilize information technology to satisfy the demands of the market. Make adjustments to production plans in timing.

The factory focuses on technological innovation in the production process Make use of current technologies as well as develop new ones Make the production technology of the product Double glazing glass production line ce certification Stay competitive in the market