Description:

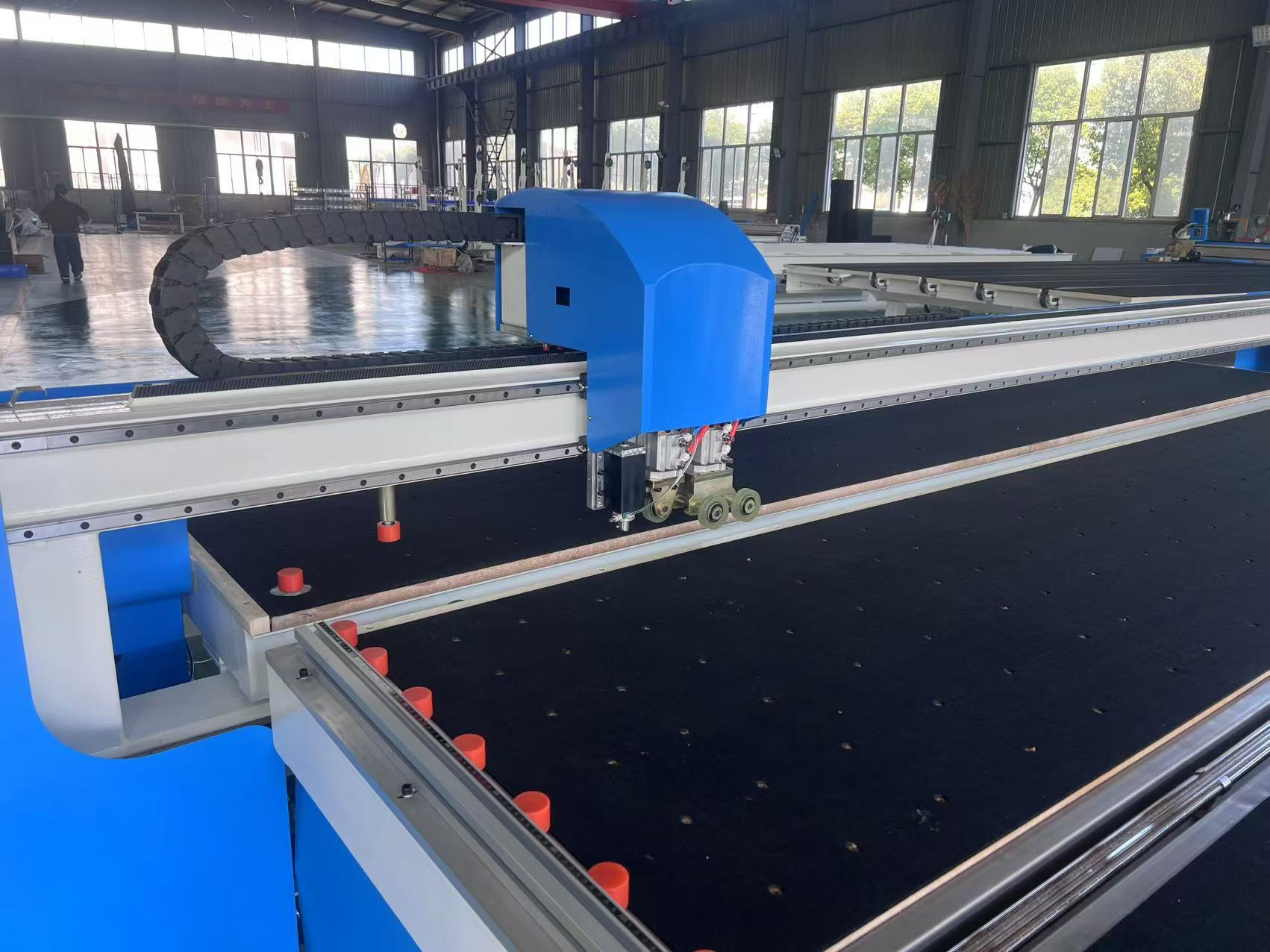

Our company research and development production SLM-3826 type high precision twin-cutter full auto laminated glass cutting machine is widely applied in thick plate glass, laminated glass. The cutting equipment operation is convenient, reliable stability, cutting efficiency and high precision.

Product introduction:

National standard square pipe welding frame. Adopt high-precision rack transmission. PLC and imported electrical components, Servo motor, LCD display, man-machine interface, more convenient operation, stable performance. Cutting speed can be set directly. The cutting positions of the upper and lower cutter heads are consistent, the matching degree is high, and the breaking piece is easy.

Features:

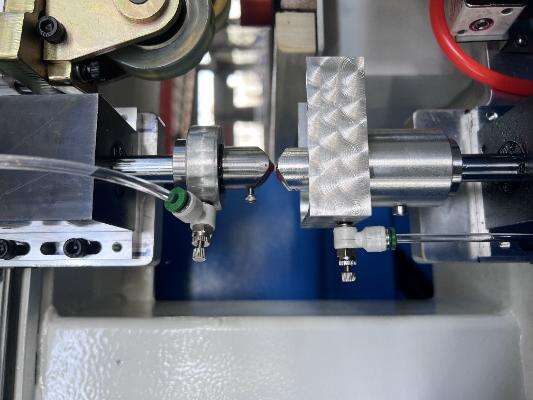

1/ The cutting positions of the upper and lower cutter heads are consistent

2/ Upper cutter with broken wheel, automatically press the lower layer of glass;

3/ When the next lever is broken, there is a pneumatic pressure to ensure the effect of breaking

4/Heating and breaking

| Cutting precision: | ≤±1mm |

| Diagonal accuracy: | ≤±2mm/m |

| Max. Cutting size : | 2500×2000mm/3770*2550mm(special size can be customized) |

| Min. Cutting size: | 100*100mm |

| Cutting thickness: | 2+0.38+2----8+3.04+8mm |

| Cutting efficiency: | 1sheet/2—4min |

| Cutter life: | 30,000m--50,000m |

| Operator: | 1-2 people |

| Machine dimension : | SLM-3826 ( 4800*2150*1150mm) SLM-2621 (3400*2400*1150mm) |

| Machine configuration | |

| Equipment frame structure: | GB thick wall rectangular pipe welding |

| Straight guideway: | Taiwan silver straight square guideway |

| Pneumatic components: | Airtac |

| Motor: | Inovance Servo |

| Driver: | Inovance |

| PLC: | DELTA |

| Touch screen: | Haiwei (remote control) |

| Platform board: | original imported E0 grade high density board from Taiwan |

| Felt: | original imported felt from Taiwan |

| Fan: | 4KW 2 sets made in China |

| Steel plate: | 1. 2 mm thickness of outer shell |

| Heating tube: | light wave infrared |

Company Profile

Our friendly team would love to hear from you!