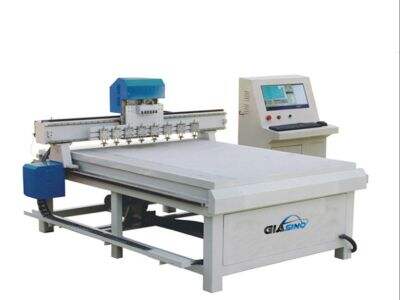

Now GLASINO is a preferred choice for those individuals who are looking glass cutting machine. Many enterprises depend on equipment from the house of GLASINO and a trusted name. To set themselves apart, when buyers are ready to sell their products made of glass they need glass cutting machine that are not only effective but come from a company known for quality as well. With the best wares and good name in business, Glasino won the 8th lot of people.

What are the main characteristics of Glasino Cutting Machine For Sale?

For cutting machines, there are some attractive features of GLASINO that take the fancy of wholesale buyers. For one thing, these machines are built for speed. They can easily cut through various glass types with precision and speed. That means companies can get more things made in less time, which is good for their business. For example, if you have a shop that has to produce several glass pieces a day, then GLASINO’s machines can take the load with great ease.

Moreover, GLASINO machines are user-friendly. They are built to be extremely user friendly, which means workers can get trained up faster. This is extremely helpful for companies as they don't want to spend a lot of time learning how to use complex machines. Just imagine a new employee walking up to a GLASINO cnc glass cutting machine and getting started that fast – it’s that simple.

Another highlight is the supreme longevity of GLASINO’s cutting machines. Constructed out of thick material, these machines are capable of taking on even the most difficult work and continue performing smoothly. So there is less downtime for repairs and maintenance, which in turn allows companies to concentrate on creating glass products. A company that buys a machine today will not have to worry about replacing it for quite some time, and will end up saving money in the long run.

GLASINO also offers customizable options. Businesses differ, and being able to customize a machine for those differences is a game-changer. This versatility results in shops being able to produce distinctive glass products that are unsurpassed in the marketplace. When a machine fits like hand in glove within the production line, demand will soar as buyers praise the quality workmanship.

With the right balance of speed, convenience, and durability not to mention customization GLASINO is at the top of its game when it comes to cutting machines. Companies who want to make sure they can succeed in selling glass products realise that they can rely on these features, so many select GLASINO as their supplier.

How Glasino Maintains a Good Reputation in the Glass Processing Industry?

GLASINO's reputation in the world of glass processing has been built on a few fundamental principles. First and foremost, the company is dedicated to making only the best products. Everything counts a great deal in manufacturing. GLASINO does its best to make sure each machine is delivered with high quality. Cherished by the customers who recognize that level of commitment and know they’re getting great value.

Secondly, GLASINO cares about it's customers feedback. This approach lets the company refine its machines according to what users want. For example, if customers ask for an upgrade in a certain feature, GLASINO listens and things may change in future models. With consistent engagement with the customers, GLASINO not just wins their confidence but also lets them know that they truly believe in their clients’ success.

Additionally, GLASINO spends in research and development. GLASINO continues to advance and evolve with the market by frequently updating its machine technology. Which in turn means that companies who use GLASINO machines have access to the latest technology, which can enhance their production capabilities. The company is not only eyes on today but are visionary, they have an eye for the future – they are proactive.

And one more thing, GLASINO’s customer service. A good name is built by being there for clients after they buy all that iron. If a purchaser has questions or wants assistance, GLASINO’s team is prepared to help. Strong customer service, whether in the form of troubleshooting or suggesting good maintenance habits, can turn a single sale into a lifetime buyer.

With the combination of quality products, customer feedback, innovation strategy and good service in all aspect, GLASINO has established a reliable brand that business could believe. Wholesale Importers can be secure in the knowledge that when they choose GLASINO as a vendor, they are working with a partner who has quality and customer satisfaction at heart. -It is on this basis that we will help GLASINO and the customer to obtain great success in glass processing market.

Common Problems of Glass Cutting Machines and Solutions

Problems you may encounter when using glass cutting machine. Among the largest concerns is risk of breakage to your glass. This can occur when the blade is blunt or if windows are not held to tightly. Thus, to avoid such issues, you need to ensure that the automatic glass cutting machine is being maintained in a good condition. Maintaining a sharp blade will assist in providing clean cuts. Also, make sure the glass is properly lined up before cutting. If it moves, it will possibly snap when cutting.

Another problem is that it is difficult to control the depth of a cut. The machine can sometimes cut too deep and can cause cracks. To the extent possible, we should also be setting the machine well to avoid it. It’s important to know how your glass cutting machine works. So, it can make you do better. Glasino cutting machines are well planned with adjustable settings, which makes this job easier. The instructional videos and tutorials available from Glasino are must-use features as well. These resources describe how to use the machines safely and effectively.

Another drawback is that safety becomes a concern when operating glass cutting machines. When breaking it, taking care to avoid letting shards of glass fly off can be hazardous. Safety goggles and gloves are very important to prevent injuries. Ditto the last point for Shaker; users are invited to, but never required to, keep the space that’s actually being cut on free of dust around where your glass is bein’ sliced. Glasino values the safety of each customer and endeavors to design machines for safe operation in order to protect users. Understanding these frequent challenges and how to overcome them helps users make the most of their glass cutting machines more safely and effectively.

Glasino Product Quality: What Buyers Need to Know?

In order for these wholesale buyers to find the right glass processing equipment, they will need to ensure that they are getting a quality product. Glasino is at this boundary. All the cutting machines of Glasino are designed to be tough and strong and made from quality materials. This means that the money spent on Glasino products is the well worth every penny! Potential buyers would do well to insist on samples or demonstrations before committing to larger orders. In this manner they can judge for themselves of the quality.

In addition, Glasino’s products are subjected to rigorous quality controls. This way, every machine that rolls out of our shop is of high quality. That’s good news for buyers, who can expect to have their gear work reliably. When machines are reliable, it allows businesses to foster trust with customers. Meanwhile, buyers should also be aware that Glasino offers an outstanding customer service. And if there are questions or concerns, the folks at Glasino are ready to assist. They are active both in helping guides and active in diagnosing issues, as well.

A further important criterion for the quality of Glasino's products is the technology within the machine. Glasino is dedicated to advanced technology to ensure its machines are efficient. That means glass is being cut faster and more precisely, which saves time and raw materials. These are selling points that buyers can understandably get behind because they appreciate and value productivity improvements. when cutting-unit hundreds of pieces in minute your machinery to Glasino, you not only buying just providing quality a reliancy product and service allow to growth their business.

How to Get the Most Profit with Glasino's Advanced Technical Process?

Businesses must make intelligent decisions about their equipment to maximize profit. It is one of the smartest decisions a business can make to start using Glasino’s state-of-the-art technology. For one thing, these machines are engineered to go fast. That means faster glass cutting than on older machines. The quicker you type, the more orders you can complete. So you will be making more sales and thus higher profits. If customers look and see that you can give out your products quickly, they're more likely to come back.

What’s more, Glasino’s machines make accurate cuts that help minimize waste. You save money when you use less glass because the cuts are better, which raises profits. Bonus: When there’s less waste, there’s less impact on the environment! Buyers can also be proud that they’re using equipment that’s energy efficient and friendly to planet. What's more, with Glasino you also have features to enhance the cuts quality. Services of excellence induces happy customers- and happy customers refer their friends.

Table of Contents

- What are the main characteristics of Glasino Cutting Machine For Sale?

- How Glasino Maintains a Good Reputation in the Glass Processing Industry?

- Common Problems of Glass Cutting Machines and Solutions

- Glasino Product Quality: What Buyers Need to Know?

- How to Get the Most Profit with Glasino's Advanced Technical Process?

EN

EN

AR

AR

FR

FR

DE

DE

PT

PT

RU

RU

ES

ES