We often have to heat things up in factories, very high. Such as the metal being a softer material that can therefore easily be shaped, hardening it for its employment in work requiring strong or denser properties. But heating large objects like in India or China can be difficult and time consuming at times. It means lots of factories are now employing a new type heating technology, which is forced flat convection furnace. This technology is enabling them to heat materials with more potency and optimize;

Forced flat flow of heat (also known as atmospheric comfort system) is a kind Oil Refineries Contractors for Worm-grown environmental applications to warm the material higher and faster than in factory environments. How it works (Image credit: Vornado)This heater uses fans to push air over a heated material. By having more space, the heat can also travel through your materials rapidly and equally as well. It surrounds the material completely instead of only heating from one side or top.

When heating materials, one of the biggest issues is ensuring that they heat up equally throughout. Unequal temperatures across a material cause different segments to expand at differing rates, leading to the bending, warping or even cracking of that material. It can cause severe issues for those this material is being used with. The flat furnace design also aids in this regard; it ensures the material is heated uniformly. That has an impact on being successful in any type of employment containing heating.

Heating must be done very responsibly depending on the kind of factory job that is to be carried out. An application for this is the heat treatment process to strengthen metals useful for making tools or parts being produced by machining. Annealing: Softening of metals for greater workability. This requires an exact temperature for both jobs to work, and therefore also produces the desired results.

It is this kind of meticulous heating that flat convection type furnace has established a huge affinity with and the forced flat convection also serves as an excellent choice. You can program it to get to specific temperatures and hold them until you are ready. This makes sure that the products are heated uniformly as well as to best temperature level for all time of this process. Factories that are using this furnace will know for a fact they can rely on it to produce the results they want every time.

Third, the flat top gantry type forced convection furnace is often used in factories that need to be heated at once but want a cost-effective solution. Earlier methods of heating required more power and in turn, probably would be less expensive to run. The new furnace, meanwhile has improved efficiency and low energy use but is doing its job just fine.

Additionally, the flat convection furnace is able to heat more in one go with this forced method This helps factories by saving them time and money that is needed to heat up large batches of materials. The more materials that can be heated and extracted at once, the faster it is to do the whole process allowing for times when massive amounts of catechins are required.

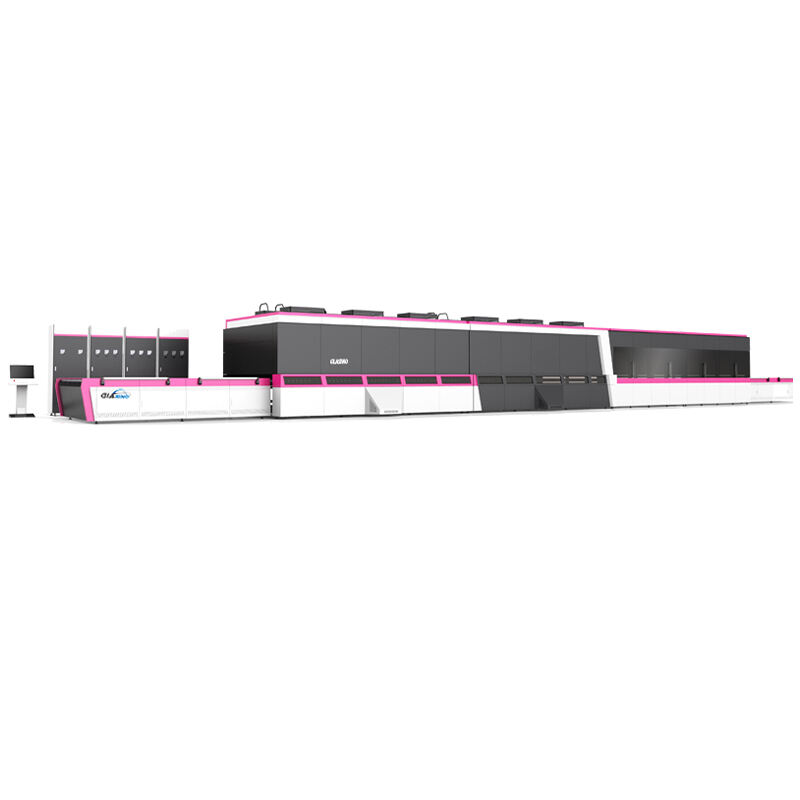

Our factory is forced flat convection furnace to take advantage of economies of scale through the introduction of advanced production equipment and technology manual work is reduced Moreover the speed of production for high-efficiency equipment tends to be faster which can quickly complete the production task and boost the speed and efficiency

The factory focuses on technological innovation in the production process Make use of current technologies as well as develop new ones Make the production technology of the product forced flat convection furnace Stay competitive in the market

forced flat convection furnace accordance with the market condition the factory can adjust the production plan according to the market conditions in order to keep up with changing market demand and maintain an advantage in the market. Create flexible production lines, and use information technology to meet the demand of the market. Modify production plans according to the basis of time.

In forced flat convection furnace to reduce the number of products that are defective, and to improve customer satisfaction, strict quality inspections are performed. A solid quality control system in place to ensure continuous quality control. Improve inspection and testing methods